Foreword

China uses forest resources as packaging materials, while European and American countries and regions have strict requirements for the packaging of imported goods: First, the use of white light foam plastic is strictly prohibited. All packaging products must be inspected by pests and diseases. For wood packaging, it is required to be fumigated and disinfected. The present situation of packaging is: corrugated cartons are used for packaging small food products such as foods, beverages, clothing, medicines and daily necessities. Air compressors, automotive engines, program-controlled switches, motorcycles and other mechanical and electrical products are generally packaged with wood products and plastic products. Large household appliances such as motors and refrigerators need to be supported by light foam cushions in ordinary corrugated boxes.

The corrugated paperboard and corrugated boxes that are commonly produced and used in the country have advantages comparable to those of other packaging materials, such as: environmental protection, recyclability, strong printability, light weight, low cost, and easy folding and forming, etc. The packaging material/container, but it also has a fatal flaw: the strength is not high and it is especially noticeable after the carton is damp. In this regard, paper packaging is difficult to match with wood packaging and plastic packaging. Because ordinary corrugated packaging boxes are not strong enough to cause dampness to fall out of the box, resulting in damages caused by the damage caused by the contents of the interior, the problem of poor packaging has to some extent restricted the export volume of certain products.

With the rapid development of China's national economy, especially after China's accession to the WTO, the export of various items has been increasing, and the demand for various packaging has also increased. How to design and manufacture high-strength packaging products using paper as materials, and more widely implement paper-based wood and paper-based plastics in the packaging field, whether it is to reduce the deforestation of limited forest resources, maintain ecological balance, reduce pollution, and protect human living environment. Therefore, it is of extremely important and far-reaching significance to reduce the damage of goods in circulation and transportation, and to make packaging really protect the contents.

Guilin Chenguang Paper Products Co., Ltd. continuously summarizes its experience in long-term production practices. In the near future, it has developed a new packaging material and packaging product with novel structure and wide applicability with independent intellectual property rights: full paper quality and high strength. Reinforced sandwich corrugated board (commonly known as "Watakawa" paperboard), as well as top and bottom flap-type packaging cartons and bolt-type packaging boxes made from the cardboard.

Enhanced sandwich corrugated board features and uses

1, protect the environment, low cost.

The corrugated paper and corrugated paper are all the materials used for the reinforced sandwich corrugated board and the manufactured packaging products. As a result, the use of paper for wood and paper for plastic molding is more widely realized, and the use of wood and non-degradable light foam is reduced, which is beneficial to ecology. Balance and environmental protection; At the same time, reinforced sandwich corrugated board and its products have the advantages of being recyclable, light weight, printable, collapsible, good cushioning performance, and low cost.

2, a reasonable structure, high strength.

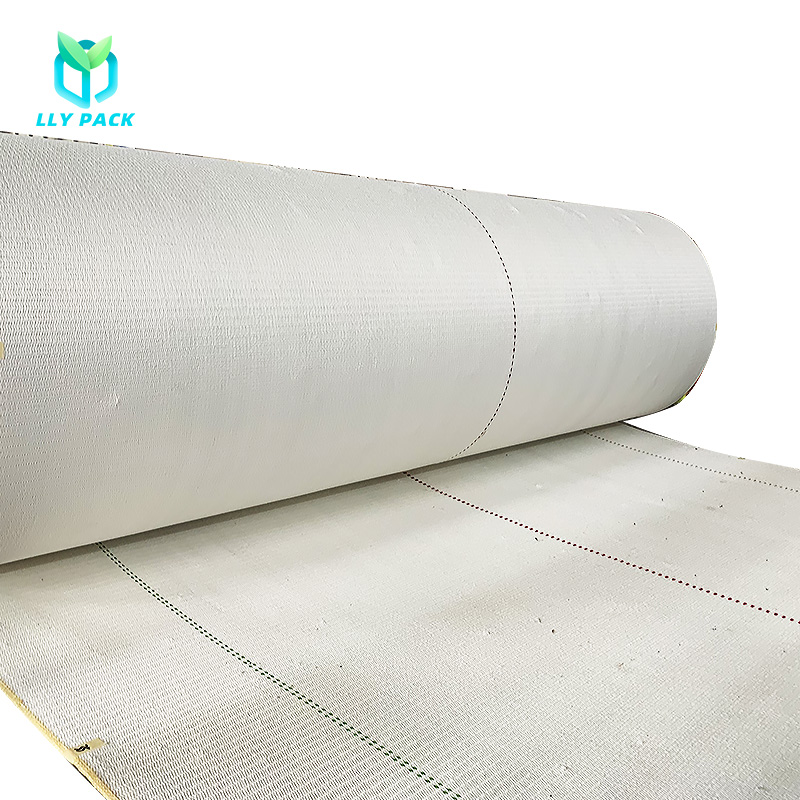

Reasonable structure makes reinforced sandwich corrugated board with high strength. After inspection and determination, the total thickness of the board is 3.2cm (the thickness can be adjusted freely), the interlayer corrugation density is 38-40楞/m, and the surface layer is five layers (quantitative 780g /m2) Ordinary corrugated board (C楞B楞), inner layer is three layers (quantitative 470g/m2) ordinary corrugated board (C楞), sandwich is three layers (quantitative 680g/m2) ordinary corrugated board (B楞) Total The paper was quantified at 1900-2000 g/m2.

(1) Side pressure strength>7350N/m2

(2) Flat compressive strength> 129850N/m2

(3) Breaking strength (tested)

(4) Flexural strength (tested)

(5) Dynamic buffer (tested)

Compared with ordinary five-layer corrugated cardboard, many physical indicators exceed the ordinary corrugated board several times or even ten times.

Compared with the same amount of honeycomb paperboard, the integrated index of the reinforced sandwich corrugated board is better.

3, improve efficiency, easy disassembly.

It is easy to connect with ordinary corrugated cardboard (3 layers, 5 layers, 7 layers) to make packaging containers for various purposes. For example: (1) The use of "reinforced sandwich corrugated board" for the cabinet air conditioner indoor unit made of the top and bottom swing cover box (see Figure 1-4), due to the compact structure (now from seven to two), can be reduced Direct packaging costs 10-15%, reducing indirect packaging costs 20-30% (packaging efficiency, packaging labor, transportation volume, storage costs, sealing tape, bags, etc.). At the same time, since the front is seamless with no nails, the integrity and aesthetic appearance of the container are improved.

(2) The use of reinforced sandwich corrugated board for the design of the air-conditioned outdoor units, refrigerators, color TVs, motorcycles and electromechanical products of the plug-bottom packaging box (see Figure 5), supporting the end of load up to 200kg. The biggest feature of the box is the use of "Watakawa" cardboard sandwich for the corrugation of the gap, the use of the plug (pin material can be wood, bamboo, plastic or paper tube) and the bottomless enclosure connected to one, greatly facilitates the heavy items Packing and picking process, especially color TV, at present the color TV package below 34 inch generally uses ordinary parcel-type carton, in the sales process, the color TV must be lifted out of the box to show debugging to the user, look after and then Inside the box, it is both troublesome and unsafe during the entire process, and it is extremely inconvenient.

(3) The use of reinforced sandwich corrugated board Corrugated Packaging Machine due to its good flatness and bending strength, if it is connected with the paper tube made legged bracket (see Figure 5, 6) can completely replace the wooden bracket, and can be forklift Or trailer shipping items.

(4) The use of reinforced sandwich corrugated board with good side pressure strength, and the structure of the five-ply paperboard can be made by slotting (see Figures 5, 6) or by using the characteristics of five-layer cardboard pressurizable lines for turning. Plane and right-angled support plates, if the surface layer cardboard is two layers (tile corrugated outward), the shock-proof buffering performance is more ideal.

4, low technical difficulty, less equipment investment.

As "enhanced sandwich corrugated board" is a cardboard produced from ordinary corrugated board, its main material is ordinary corrugated board, so it is very suitable for the production of corrugated packaging companies.

Process, process and equipment

1, the process

(1) The corrugated board production line produces corrugated board with top layer, back layer and interlayer according to the required specifications.

(2) Sandwich corrugated paperboard Corrugator Plant (three-layer, B-twist, base paper quantitative 100-115g/m2 ordinary corrugated paper), in a specialized cutting machine at a certain interval distance, the positive and negative vertical corrugation direction cut (cut off the second floor, only Leave a connection).

(3) Corrugated cardboard after cutting is combined with the inner layer on a special gluing machine (equivalent to single-faced corrugation).

(4) Trimming the blended cardboard on the slitter and slitting according to the required specifications (if it is only for cardboard, this process should be carried out after the surface layer is glued).

(5) On the ordinary gluing machine, stick with the surface layer corrugated cardboard. If the surface layer is used as the outer layer of the packing box (generally five layers of corrugated cardboard) Corrugated Line, it can be printed, die cut or grooved in the same way as ordinary corrugated boxes.

2, process flow

3, the required equipment

(1) Five-layer corrugated cardboard production line;

(2) Specialized cutting machine;

(3) Dedicated molding gluing machine;

(4) printing machine, slotting machine;

(5) Die-cutting machine;

(6) Ordinary stickers machine;

(7) Slitter.

Cost statistics

1. Material (three-layer corrugated cardboard)

(1) Surface and in-line three-layer corrugated cardboard (C or B enamel, 175g nubuck cardboard, lining paper 180g noodle, corrugated cardboard 127g corrugated paper) 1.65 yuan / single m2 × 2 = 3.58 yuan / double m2

(2) corrugated sandwich layer, surface, in, corrugated paper are 127g corrugated paper, 1.28 yuan × 1.6 = 2.05 yuan / m2

2, processing fees (cutting, forming, blending, slitting)

(1) Auxiliary material: 0.54 yuan/m2

(2) Utilities: 0.05 yuan/m2

(3) Management fee: 0.25 yuan/m2

(4) Profit: 0.80 yuan/m2

(5) Tax: 0.22 yuan/m2

(6) Others: 0.27 yuan/m2

Total: 8 yuan/m2 (production company sales price)

To sum up, "Strengthened Corrugated Corrugated Cardboard" has fully utilized the mechanics of multi-directional support due to its structure. High-strength corrugated paperboard has been deformed by a unique process and integrated with the best mechanical structure, resulting in such high strength. The six sides of the box made of corrugated cardboard form a strong tubular matrix, which can resist the pressure and collision from all six sides in an all-round way, and can effectively prevent the damage of the articles in the box, especially the large volume of the packaging. Products and fragile products can show its advantages. As "enhanced sandwich corrugated board" is a full-paper packaging product, it has the advantages of light weight, high strength, good cushioning performance, etc. It can effectively replace the foamed plastic as the liner and support block of product packaging, preventing external force from packaging The oppression and collision of the goods avoid the problems of package collapse, environmental protection and epidemics. Because "enhanced sandwich corrugated board" makes full use of the principle of mechanical structure, under the same strength requirements, it will save more materials than traditional corrugated cardboard and honeycomb board, so the production cost will be lower. It can be said that "enhanced sandwich corrugated board" and its various types of paper product packaging boxes used to make it are a project that benefits the country and the people.