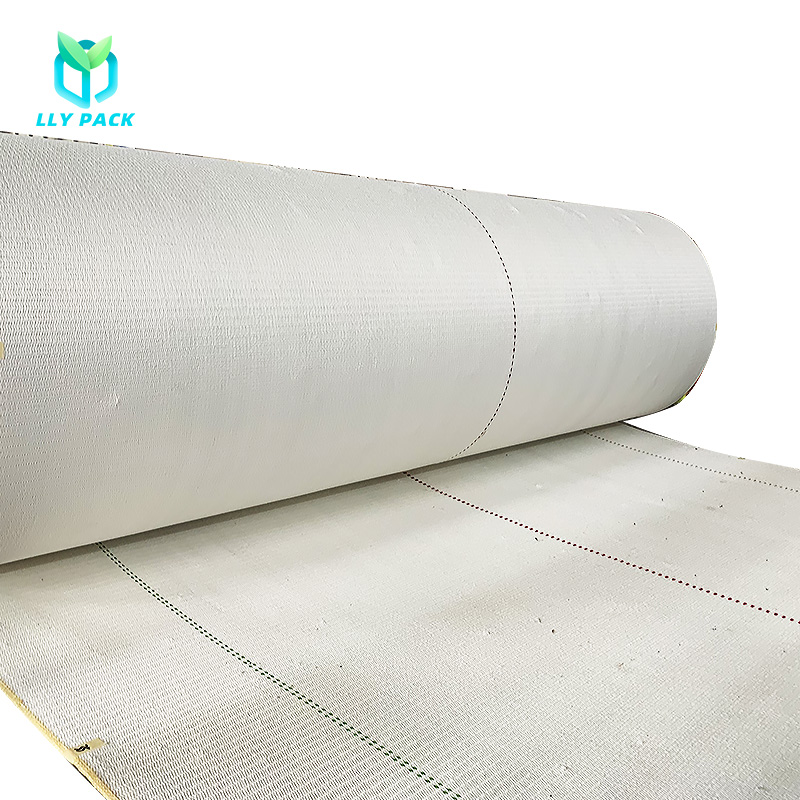

Four-layer corrugated cardboard structure

Four-layer corrugated paperboard is used to coat two layers of corrugated paper with adhesives with special properties, so that the glue penetrates between the fibers of the paper, changes the softness of the paper, and composites the two layers of corrugated paper. They are glued together, rolled into a crucible under heating conditions, and then glued with the surface box cardboard to form a strong, stiff four-layer corrugated cardboard, the corrugated core type is double core paper adhesive Double-arched "honeycomb network" structure formed by corrugating rollers. The double arch of four-layer corrugated cardboard still adopts the ordinary corrugated shape - UV-shaped corrugated, and can be divided into 2A, 2B, 2C type according to the corrugated type.

Four-layer corrugated board performance

Reinforced corrugated board, double-arched corrugated board, and UPS combined corrugated board all belong to four-layer corrugated board. The main difference is the processing equipment. The four-layer corrugated paperboard has high technical content and good performance, which helps to enrich the existing tile type and expand the market advantages. The four-layer composite corrugated carton is suitable for the packaging of products with high shock and pressure resistance requirements, such as transportation packaging of vegetables, fruits and other agricultural and sideline products, and can replace the existing common standard five-layer corrugated cardboard boxes. Compared with five-layer corrugated board, four-layer corrugated board saves one layer of corrugated paper, which can save cost by more than 10% and reduce the cost of the cartons.

In Japan, Europe and the United States and other countries and regions, the development and application of four-layer corrugated paperboard has become quite common. It has only started in recent years in China. A few corrugated manufacturers in China have begun to introduce this new type of corrugated board manufacturing process, but have not yet been promoted. application.

Functional expansion of four-layer corrugated cardboard

The function of the four-layer corrugated paperboard is very expandable, such as the closed structure between two-layer corrugated paper of 2A four-layer corrugated cardboard, which facilitates the filling of special materials between the corrugated paperboards, so that the performance of corrugated paperboards is expanded. IF iron foil is a good filler material.

Filling a corrugated cardboard box made of four-layer corrugated cardboard with IF foil not only enhances the resistance to pressure, breakage, and puncture resistance, but also has functions such as water resistance, moisture resistance, and enhanced electrostatic shielding and electromagnetic shielding. It is particularly suitable for packaging aquatic products, fruits and vegetables. , tea, electronic instruments, semiconductor products and mechanical and electrical parts and other products.

We can also fill a lot of other materials, get a lot of special performance and enhance the functionality of the cardboard without affecting the appearance and printability of the carton.

Four-layer corrugated cardboard production

In China, the production of such Corrugated Line is achieved through the introduction of the entire production line, which is undoubtedly difficult for the existing three- and five-layer corrugated board production lines. In response to this situation, Beijing Shouhang Wanyuan Packaging Machinery Co., Ltd. Corrugated Cardboard Cutting Machine has successfully developed a device that can maximize the use of existing equipment without affecting the normal production of the original three- or five-layer corrugated board production line. The addition of a special gluing equipment (two-arch gluing machine for sticking two core papers into a composite corrugating medium) will meet the requirement for the production of four-layer corrugated board. Moreover, this newly added equipment is easy to install and place on site, and an independent production line can be formed without moving the ground positions of individual stand-alone corrugated cardboard production lines.

The basic process of this special double-arch gluing machine is: after preheating, rolling glue is applied, and after the process of gluing, gluing, squeegeeing, gluing, and adhesive bonding, the adhesive bonding and pressure bonding are completed Corrugated Box Machine. In the steps, the two core papers are regularly bonded into a composite corrugated core paper, and then the single-sided machine is introduced to form a composite corrugated cardboard.

Control Technology of Adhesion Poor in Four-layer Corrugated Paperboard

The four-layer corrugated cardboard Corrugator Planthas a layer of corrugating medium in the corrugated medium, and a layer of glue is also applied between the two layers of corrugated medium to increase the hardness and thickness of the double-layer corrugated medium after drying. The strength of three-layer corrugated board more than doubled.

1. Four-layer corrugated board adhesive points

(1) When corrugated paper is compounded, the coating glue will increase the water content of the corrugated core paper, and after the adhesive is dried, it will prevent the embrittlement of the corrugated medium. Therefore, the water content is small, the permeability is low, and the uniform coating is easy to choose. Corrugated paper composite adhesives are critical.

(2) On the premise of satisfying the post-composite bonding strength, the principle of the gluing amount is as small as possible.

(3) It is also important to control the humidity of the composite corrugated medium before pressing the corrugated medium. Humidity not only affects the molding, but also causes debonding during compounding; when the humidity is too low, the peak will be embrittled and broken when the corrugation is bent.

(4) The corrugated type of four-layer corrugated cardboard should be specially designed and calculated by a professional roll company based on the thickness of two layers of corrugated paper and a layer of glue to produce an ideal corrugated cardboard.

(5) When processing four-layer corrugated cardboard on a vacuum suction type single-sided machine, attention should be paid to adjusting the adsorption system (position, clearance, and air volume of the suction hood and corrugating roll) and the heating system; the composite corrugated medium must have higher requirements. The Corrugated Cardboard Production Line temperature can transfer heat to the peak and meet the gelatinization temperature requirement. The Corrugated Carton Machine thicker corrugated core paper will increase in hardness, and it will be easily removed from the corrugating roll after forming, affecting the gluing and compounding, resulting in high and low defects, collapses, degumming, and “wood ear” quality problems. Therefore, it is necessary to have enough air volume for adsorption. With negative pressure and heating temperature, it can ensure smooth coating after the corrugated board is formed.

2. The relationship between speed and cardboard quality

(1) The ideal adjustment speed should be the most stable and economical speed of the Corrugated Carton Machine.

(2) The strength and humidity of the paper should be suitable for the speed of the vehicle.

(3) The fluctuation of the vehicle speed will affect the humidity control of the paper. The more stable the vehicle speed, the more stable the humidity control of each layer of paper, and the more stable the quality of the paperboard, a good heating system is necessary.