EnglishEspañolPortuguêsDeutschहिंदी日本語ខ្មែរNederlandsالعربية한국어मराठीMalagasyItalianoPolskiSvenskaελληνικάPусскийภาษาไทยTürkShqipMagyarViệtSamoaМонголMaltiIndonesia FrançaisMelayuҚазақшаYorùbáবাঙালিעִברִיתGàidhligSomaliEesti keelKreyòl Ayisyennorskčeštinaفارسیతెలుగుမြန်မာBosanskiMaoriქართულიRomânăбеларускіУкраїнськаతమిళGaeilgeSuomalainenپښتوລາວհայերենSlovenščinaFilipinoO'zbekÍslenskaייִדישLatviešuGalegoFryskनेपालीKurdîCatalàбългарскиHawaiianHrvatskiਪੰਜਾਬੀWong JawaKiswahililëtzebuergeschisiXhosaEuskalSundaZuluગુજરાતીТоҷикӣ

- Huis

- Over ons

-

Product List

- Golflijn

- Gegolfde machine >

-

Golde machine -reserveonderdelen >

- Roterend gewricht

- Kam voor Slitter Scorer

- Remblokken

- Diafragmpomp voor lijm

- Afvalpapierstripper

- Uitbreiding

- Flexibele metalen slang

- Slijpschijf

- Tape voor splicer

- Gegolfde roller

- Slijpmes

- Overheadbrug tractieriem

- Zonnescherm

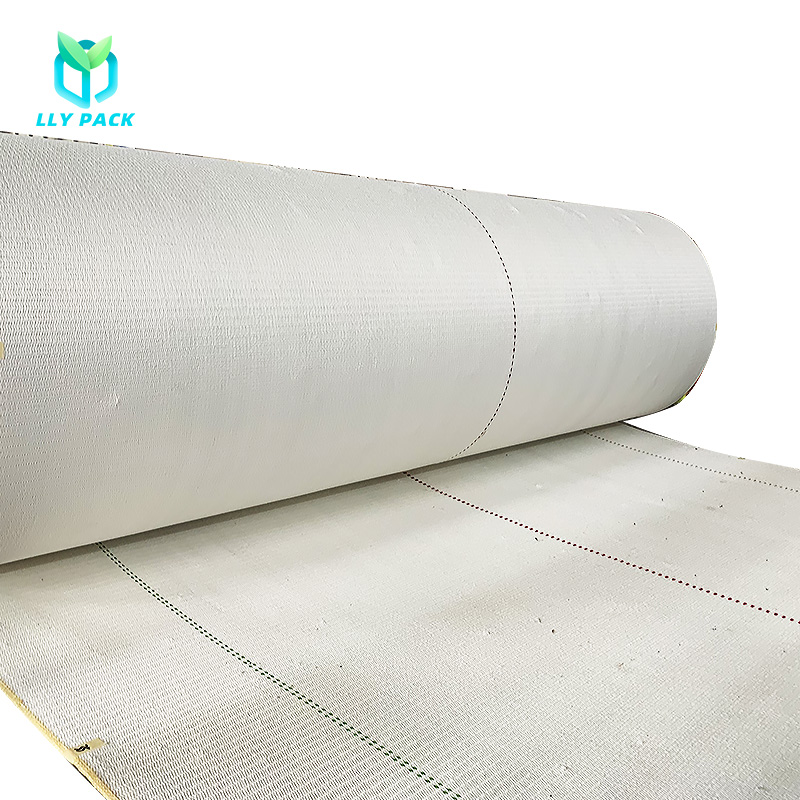

- Transportband

- NC snijmes

- Stoomval

- Pneumatische cilinders

- Pneumatische rem

- Luchtboelveer

- Waterring vacuümpomp

- Golfmachines smeermiddel

- Rubberen spacer

- Titanium-vergulde spacer

- Flexo printer slotter

- Flexo -printermachine >

-

Printer -reserveonderdelen >

- koperen plaat

- Afdrukplaatrek

- ARO-pomp

- Stalen en koperen borstel

- Inktfilter

- Dokterbladen

- ANVIL COVER

- Slotting mes

- Vezelband

- Hangend frame

- Huisdier pre-strip met film

- R en bak printing kussen

- Voedingswiel

- Eénrichtingskleurig

- Rotary Die Board

- Enkele diafragmapomp

- Inktkanaal eindblok

- Rubberen diafragma

- Duckbill -klep

- Magnetische koppelingsrem

- Hangende groove strip

- Verpakkingsmachine >

- Kartonmachine >

- Kartonnen machineonderdelen >

- Dubbele faceriemen

- Stiksels lijmensysteem >

- Kartonnen snijmes >

- Wolfraamstalen mes >

- Slijpschijf

- Afvalstripper

- Verpakkingsmachine mes >

- Pre-press apparatuur >

-

Industrieel snijmes >

- Tegel Circular Saw Blade

- Metaal snijden zaagblad

- Houtsnijzaagblad

- Voedsel snijden zaagmes

- Vezelsnijmes

- Chipperblad

- Buigvorm

- Blade voor groentesnijdende machine

- Stalen dun mes

- Tsukatani Die snijdende mes

- Printer Die Cut Blade

- Masker machineblader

- Slitter Rewinder Blade

- TMR -mes

- Tabakscirculaire mes

- Roll Shear Blade

- Gekarteld mes voor verpakkingsmachine

- Papier snijdende band mes

- Dokter mes

- Ronde mes

- Three Holes Blade

- Keramisch mes

- Bandmesmes voor stof

- Bandmesmes voor sponsschuim

- Bandmesmes voor splijten machine

- Bandmesmes voor papier

- Meshouder

- Industrieel snijmes

- Freeskutter

- Hoekmolen

- Shredderblad

- V Grooving mes

- Elektrische schaar

- CNC Machine Blade & Tools

- Voedselverwerking mes

- Nieuws

- video

- Contactgegevens

- Klik Hier om onderzoek te sturen