Production of Adhesive for Single-sided Machine and Corrugated Cardboard Production Line and Related Factors Analysis

At present, the majority of domestic corrugated board production lines use starch adhesives, and their bonding quality is obvious to all. Their production methods are also varied, but their raw materials are basically the same, mainly: starch, caustic soda, borax, and some formulas are added. The amount of hydrogen peroxide, but the adhesive production process so far no major breakthrough, domestic and international still committed to research methods to improve the adhesive, its purpose is...

YCWZ2500 automatic corrugated board printing slotting machine put into mass production

China's first self-designed and manufactured corrugated board printing and Carton Box Printing Slotting Machine in Shaanxi Printing Machinery Factory, after more than ten years of continuous technological innovation and improvement, recently successfully developed and produced a computer-controlled fully-automated new model with advanced domestic level. And has begun mass production, put on the market. YCWZ2500 automatic corrugated board printing slotting machine, the whole machine adopts PC...

Production of Adhesive for Single-sided Machine and Corrugated Cardboard Production Line and Related Factors Analysis

At present, the majority of domestic corrugated board production lines use starch adhesives, and their bonding quality is obvious to all. Their production methods are also varied, but their raw materials are basically the same, mainly: starch, caustic soda, borax, and some formulas are added. The amount of hydrogen peroxide, but the adhesive production process so far no major breakthrough, domestic and international still committed to research methods to improve the adhesive, its purpose is...

The Influence of Printing Paste of Cardboard Box Corrugated Cardboard on Different Surfaces

The Influence of Printing Paste of Cardboard Box Corrugated Cardboard on Different Surfaces Wave surface curvature effect The high-temperature paste is a starch gelatinized cooked glue as a carrier to form a mixture of various ingredients. There is a lot of moisture in the paste itself. In the paste of wavy and face paper, there is a lot of moisture in the paste. This kind of water is the need of instant reaction, and it also affects the corrugated paperboard, and fits together. Balance the...

Corrugated roller affects cardboard quality in six aspects

The quality of corrugating rolls directly affects the cost of corrugated board production. Ordinary companies occasionally test corrugated rolls. So, what aspects of the detection will affect the corrugated board? Let's talk about it below. First, corrugated roller spacing The distance between the two peaks is also calculated by the number of corrugations within a certain distance. Generally, the larger the lay length, the more unfavorable for printing, but the twist rate of the crepe is...

Pure water machine corrugated cardboard e-commerce buffer packaging design

BAIDU_CLB_fillSlot("858283"); Since the industrial revolution, global water resources have been polluted and destroyed as never before, which has accelerated the rapid development of the water purifier industry, especially the pure water machine has been widely promoted and applied. The pure water machine is also called a water purifier and a filter. It is a small water treatment equipment that deeply purifies the water. However, in the process of storage, transportation and sales, the pure...

[Corrugated cardboard technology] Quality defects caused by pit machine "detoxification"

There are many influencing factors in the production process of a cardboard, including temperature, speed, raw materials, adhesives, equipment adjustment, personnel operation level, responsibility, etc. Quality problems should be adjusted and resolved from the above aspects. The pit machine is the core part of the cardboard. The pit machine often has some bad products that affect the quality of the cardboard. Based on my own experience, the author lists some problems and solutions for your...

Corrugated cardboard box "skin care method": the twelve classic tricks out of the cardboard box

When netizens voted for the beauty queen "Chun Chun" (Li Yuchun) to apply thick moisturizer to their fair and pink skin frequently, it was a painful time for the friends engaged in corrugated packaging. In this dry season, doing a good job of carton moisturizing care has become the top priority for managers at all levels. And don't complain about the carton customers being too picky, the carton burst line is really unsightly. If you are invited by a client to go to heaven and earth, you will...

The corrugated design of micro corrugated cardboard and the structure of corrugated roller

One of the characteristics of micro corrugations is the large number of flutes, the light weight of corrugated base paper and the low strength. Take the number of flutes per 300 mm as an example: G type is 185 ± 12, N type is 200 ± 15, O type is 267, and B type is 50 ± 2. For a pair of corrugated rollers with the same diameter, the number of fine corrugated corrugations increased by 3 to 5 times compared to B-type corrugations. It can be seen that the tension during paper feeding and forming...

Corrugated carton nail box machine equipment features

Carton equipment adjustment should avoid blindness, adjust the position of the main baffle, the left and right baffles and the positions of the upper and lower nail heads according to the carton's rocking cover. It should be noted that the left and right baffles cannot be clamped too tightly, and the cardboard can be smoothly inserted and pulled Out. After the mechanical adjustment is completed, set the touch screen computer: such as carton height = original carton height -40mm, carton nail...

Brief introduction to the technical requirements of corrugated rolls for cardboard production line

Once, when I was teaching a carton compression design and influencing factors course in an enterprise, I raised a technical issue affecting the corrugated forming for the decision-making level, management personnel, engineering technology and front-line operators of the enterprise, namely Corrugated roller's middle-high problem. As a result, all managers are not clear, and only one operator knows a little or two, but he can't tell what is going on. This shows that some companies do not pay...

Corrugated paper cross-cutting machine transformation plan

Today's corrugated paper cross-cutting machines are mainly divided into mechanical knives and computer knives. From the control system, computer knives are divided into DC systems and AC frequency conversion systems. The mechanical knife is mainly driven by the main motor to simultaneously drive the double-sided machine and the cross-cutting machine, and the cutting length is adjusted by adjusting the transmission ratio of the mechanical stepless speed regulation box between the main motor and...

Corrugated base paper, cardboard and carton testing equipment and testing methods commonly used in the UK

So far, there has not been a truly scientific and accurate test on the characteristics and components of corrugated board. This is because there will be many uncertain factors in the detection process, or it depends on the processing method of paper, cardboard and carton. In addition, in the detection area, the temperature, humidity, the operation of the detection device and the changes in the contents of the carton are also the reasons. One. However, it should be wise to establish some guiding...

How to deal with the quality failure of corrugated cardboard printing machine

The printing equipment of corrugated cardboard printing machine integrates the functions of printing, slitting and indentation production. The structure of the equipment is simple, the area is small, the operation method is simple, and the quality is easy to control. However, if the equipment is aging or the machine is not properly adjusted, some quality failures are prone to occur during printing. The classification analysis is as follows: 1. Dirty version, pasted version or unclear image and...

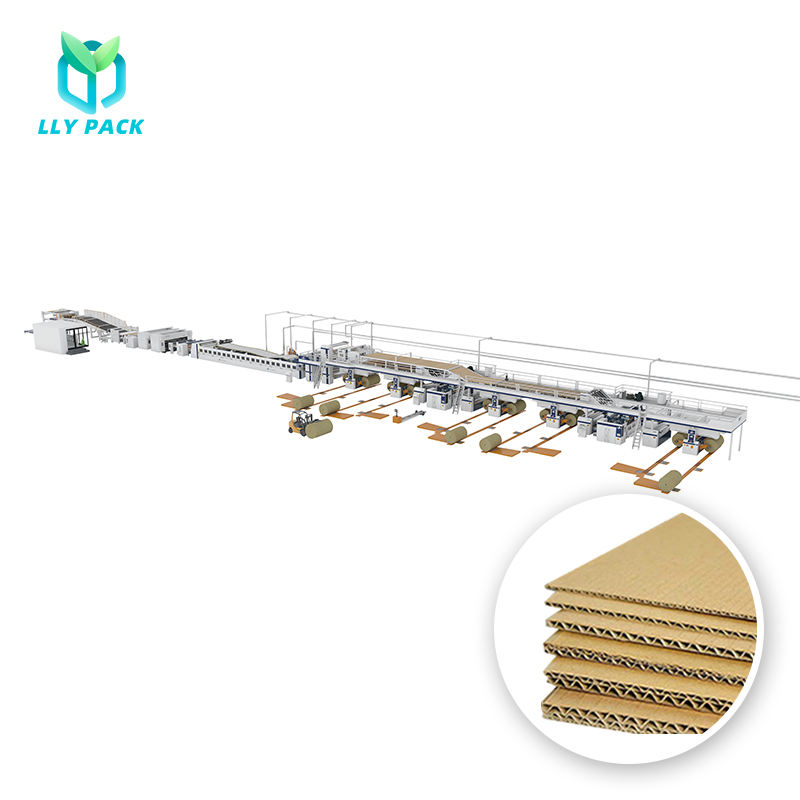

Corrugated machine production management system (1)

The corrugator production management system is a computer control system for assisting the automatic production of corrugating machines. It uses a precision sensor (SENSOR) and computer's fast calculation to perform a series of detections of corrugating machine equipment at appropriate timings. And control, simulate artificial operation, these controls include vehicle speed adjustment, gap adjustment, paste adjustment, raw paper material control, paper roll remaining amount calculation,...